What Is The Meaning Of Tempered Glass?

September 17, 2024 5:01 pmTempered glass, also known as toughened glass or safety glass, is a type of glass that has been processed through controlled thermal or chemical treatments to increase its strength compared to normal glass. This process makes it much more resistant to impact and thermal stress, making it a preferred choice for a variety of applications where strength and safety are crucial. In this blog, we will delve into the details of tempered glass, exploring its manufacturing process, benefits, applications, and why it is considered a particularly strong material.

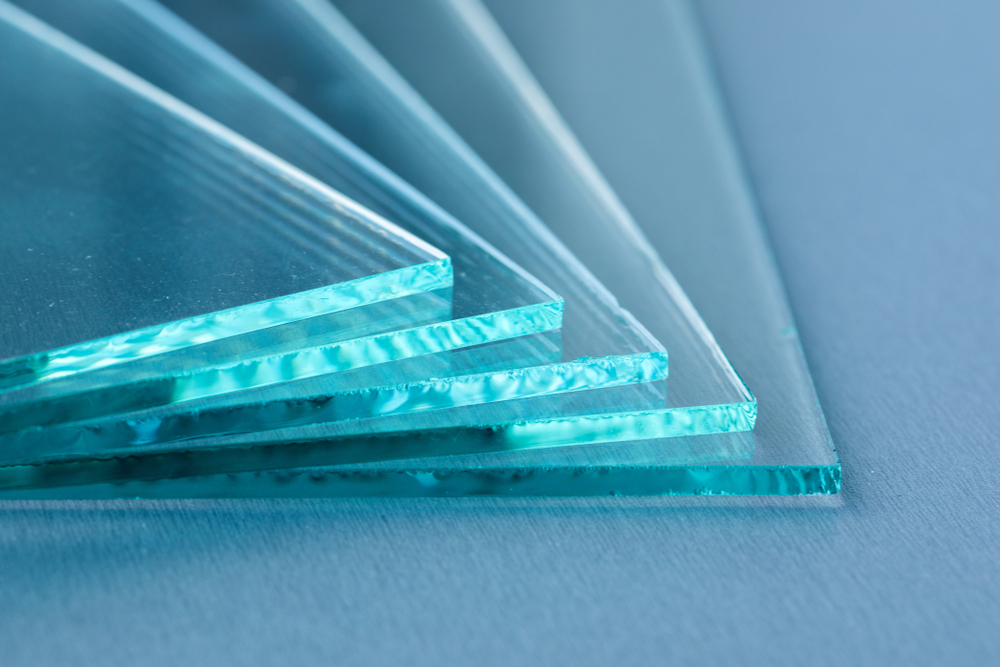

What Is Tempered Glass?

Tempered glass is a type of safety glass that is made by heating it to a high temperature and then rapidly cooling it. This process, known as tempering, puts the outer surfaces of the glass into compression and the inner surfaces into tension, which enhances the glass’s overall strength and resilience. As a result, tempered glass is much tougher than regular glass and is designed to withstand significant stress and impact.

How Is Tempered Glass Made?

The production of tempered glass involves several key steps:

- Heating: The glass is first heated in a furnace to a temperature of about 620°C to 650°C (1148°F to 1202°F). At this temperature, the glass becomes soft and malleable.

- Forming: Once heated, the glass is formed into the desired shape. This can involve cutting it to size or shaping it to fit specific applications.

- Cooling: The heated glass is then rapidly cooled using a process called quenching. This involves blowing air onto the glass to cool it quickly and evenly. The rapid cooling causes the surface of the glass to harden while the interior remains slightly softer.

- Inspection and Cutting: After cooling, the tempered glass is inspected for any defects and cut to the required dimensions. Once cut, it cannot be re-processed or altered.

Why Is Tempered Glass Considered a Particularly Strong Material?

Tempered glass’s strength comes from the tempering process. Here are some reasons why it is considered a particularly strong material:

Increased Strength

The tempering process increases the glass’s strength, making it up to five times stronger than untreated glass of the same thickness. This strength allows tempered glass to withstand high impact forces and heavy loads without breaking.

Thermal Resistance

Tempered glass is highly resistant to thermal stress. It can withstand sudden changes in temperature without cracking or breaking. This makes it ideal for applications where temperature fluctuations are common.

Safety Features

When tempered glass does break, it shatters into small, blunt pieces rather than sharp, dangerous shards. This is a critical safety feature that minimizes the risk of injury, making it an essential choice for applications where safety is a priority.

Applications of Tempered Glass

Tempered glass is used in a wide range of applications due to its strength and safety features. Some common uses include:

Architectural Glass

Tempered glass is widely used in building facades, windows, and glass doors. Its strength and thermal resistance make it suitable for both exterior and interior applications. It is often used in high-rise buildings and commercial properties.

Shower Doors

In bathrooms, tempered glass is commonly used for shower doors and enclosures. The ability to withstand temperature changes and high impact makes it ideal for this environment.

Automotive Glass

Automobile manufacturers use tempered glass for side and rear windows. The strength and safety features of tempered glass help protect passengers in case of an accident.

Glass Tables and Shelving

Tempered glass is used in furniture such as glass tables and shelves. Its durability and resistance to impact ensure that it can handle everyday use without breaking.

Glass Partitions

In offices and public spaces, tempered glass is used for partitions and room dividers. Its strength and safety features make it a practical choice for these applications.

Advantages of Tempered Glass

Tempered glass offers several advantages over regular glass and other materials. Here are some key benefits:

Durability

The increased strength of tempered glass makes it more durable and less likely to break under stress or impact. This durability translates to longer-lasting products and fewer replacements.

Safety

The safety features of tempered glass, such as its ability to shatter into small, blunt pieces, reduce the risk of injury. This makes it a safer option for a variety of applications.

Thermal Stability

Tempered glass can handle high temperatures and sudden changes in temperature without breaking. This thermal stability makes it suitable for environments with fluctuating temperatures.

Aesthetic Appeal

Tempered glass has a clean, modern appearance that enhances the aesthetic appeal of buildings, furniture, and other products. It can be produced in various thicknesses and finishes to suit different design needs.

Disadvantages of Tempered Glass

While tempered glass has many benefits, there are also some disadvantages to consider:

Cost

Tempered glass is more expensive than regular glass due to the additional manufacturing processes involved. This higher cost can be a consideration for budget-conscious projects.

Non-Modifiable

Once tempered glass has been processed, it cannot be cut or modified. This means that any changes to the design or dimensions must be made before the tempering process.

Fragility

Although tempered glass is stronger than regular glass, it can still break under extreme conditions. However, the safety features reduce the risk of serious injury.

Conclusion

Tempered glass, or toughened glass, is a particularly strong material that offers enhanced strength, thermal resistance, and safety compared to regular glass. The tempering process, which involves heating and rapid cooling, gives the glass its remarkable properties, making it suitable for a wide range of applications from architecture to automotive use.

By understanding what tempered glass is and how it is made, you can better appreciate its benefits and applications. Whether you’re considering it for a construction project, a piece of furniture, or vehicle windows, tempered glass’s durability and safety features make it a smart choice for many needs.

Need Custom Glass in Twin Cities Metro, MN?

Custom Glass & Screen has been servicing Twin Cities since 1975. We repair custom and insulated glass and screens for windows, doors, shelving, showers, mirrors, tabletops, fireplaces, storefronts, porches, and more. We are also a family-owned company associated with the NFID. We have a highly trained staff that is here to help with anything that you need, so stop in, email, or give us a call today!

Categorised in: Tempered Glass

This post was written by admin